GrainScope: Ensuring Consistency in AI-Based Grain Quality Assessment

- Grainkart Private Limited

- Mar 8, 2025

- 1 min read

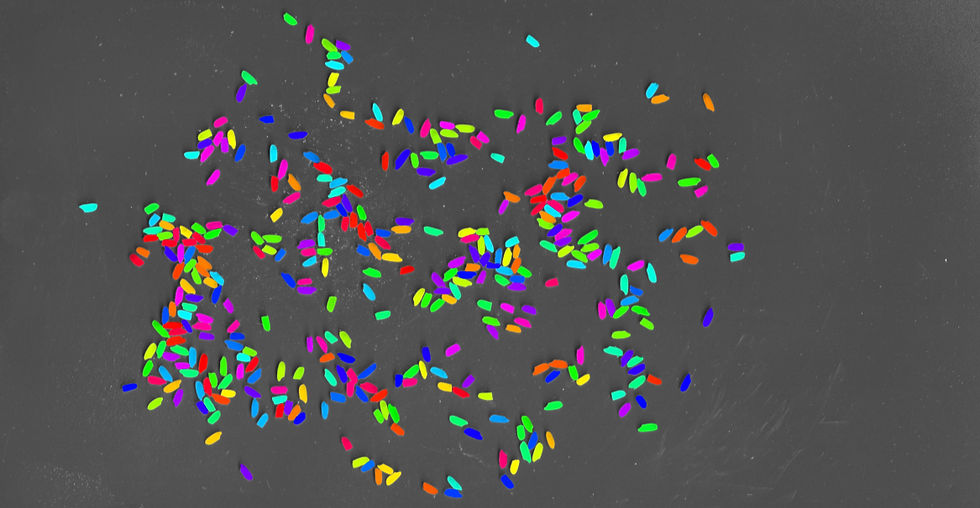

Democratizing grain quality assessment through AI-driven analyzers like GrainScope requires a well-diversified dataset and a robust set of color correction algorithms. One of the primary reasons for variations in classification across different machines is the lack of sufficient or relevant training data. Variability in imaging conditions, scanner calibration, and environmental factors can lead to inconsistent results, making it crucial to incorporate diverse samples covering a wide range of grain types, lighting conditions, and possible defects.

To mitigate classification errors, advanced color correction techniques must be implemented to normalize image inputs before analysis. Inconsistent color calibration, particularly due to differences in hardware or wear and tear of scanning devices, can mislead the AI model. Proper standardization of preprocessing pipelines can significantly improve reliability.

Additionally, report subjectivity is another challenge in grain quality assessment. Different interpretations of quality parameters by various stakeholders can lead to inconsistencies. AI-based systems must align with standardized grading metrics, ensuring transparency and objectivity in results. Continuous dataset updates and validation against real-world samples can further enhance the system’s accuracy and credibility.

By addressing these factors, GrainScope and similar AI-based analyzers can achieve greater reliability, minimizing machine-to-machine variations and ensuring fair and accurate grain quality assessment across different environments.

Comments